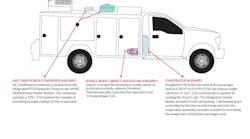

INDIANAPOLIS. VMAC has announced its latest innovation concept, the HVAC System for VMAC Multifunction. The HVAC System will eliminate truck idling on the job site, reduce operating costs and provide operators with a climate-controlled vehicle year-round, company representatives explained during a press event at the Work Truck Show.

“The HVAC System will be integrated with the VMAC Multifunction, making it the first and only engineered solution for medium duty truck-cab heating and cooling, eliminating service truck idling on the job site year-round,” says Mike Pettigrew, VMAC’s Marketing Manager. “The new HVAC System will allow operators to seek relief from extreme weather conditions, all without idling their truck.”

The HVAC System for VMAC Multifunction will offer operators a climate-controlled safe-zone when they’re working in extreme weather conditions, whether it’s sub-zero temperatures, wet and windy, or sweltering hot.

“Operators will be able to turn on the heat when it’s cold, and turn on the air conditioning when it’s hot, all without idling the truck,” says Pettigrew. “In addition, the HVAC System will heat the truck’s tool cabinets, ensuring tools and equipment are protected from freezing and rusting, even in the coldest temperatures.”

The HVAC System for VMAC Multifunction is being designed due to requests from Caterpillar dealers across North America for a solution to eliminate truck idling on the jobsite in all weather, according to the company. VMAC is currently working with Finning, the largest CAT dealer in the world, to develop the HVAC System to their specifications and requirements. By eliminating the operator’s need to idle the truck on the jobsite to heat or cool their truck, fuel usage will be reduced and hundreds of operating hours on each truck’s engine will be saved each year.

Recent field tests show that up to $5,800 in fuel can be saved each year, on top of savings in truck maintenance costs. Reducing engine hours allows for longer intervals between truck servicing, improving truck life and warranty.

An added benefit to the HVAC System for VMAC Multifunction is the opportunity to lower a fleet’s carbon footprint and environmental impact. With many municipalities enforcing strict anti-idling bylaws, fleet managers can ensure their fleets are following these regulations.

“The HVAC System for Multifunction is an innovation we’re particularly excited about because it perfectly aligns with VMAC’s promise to give our customers and industry partners the products and solutions they need to work more profitably and sustainably,” explains Pettigrew.

The HVAC System for VMAC Multifunction is slated to be released by 2020.

DTM70 now available for Ram Trucks

VMAC has also released its newest Direct-Transmission Mounted PTO Driven Air Compressor, designed specifically for RAM trucks. The DTM70 is the world’s first direct-transmission mounted PTO driven air compressor, currently available for Ford F-250 to F-750 Power Stroke Diesel trucks, and now RAM 3500 to 5500 chassis cab Cummins Diesel trucks.

“We’re pleased to be expanding our Direct-Transmission Mounted PTO Driven Air Compressor product line,” says Barry Fitzgerald, VMAC’s Engineering Manager. “We’ve seen a major demand for a DTM70 application for RAM, and it’s VMAC’s priority to deliver the products and systems that our customers and industry partners are requesting.”

The DTM70 Air Compressor produces up to 70 CFM at 100 psi (175 psi max) and is very popular in industries such as commercial tire services, oil and gas mobile mechanics, utility servicing and heavy equipment repair. It is powerful enough to use for OTR tire inflation, 1” impact wrenches, 60 lb jackhammers and pavement breakers, vertical/horizontal grinders and sanders and other small to medium sized air tools with high air demand.

The VMAC DTM70 is for customers who are concerned with saving space and reducing weight on their service trucks. It is a popular choice for those looking to save space on their truck decks, as it is installed under the truck. The complete DTM70 system weighs just 150 lbs, making it a lightweight choice compared to traditional deck-mount air compressors or other underdeck systems.

“The DTM70 offers many advantages over traditional underdeck air compressors,” adds Pettigrew. “Not only is it lightweight, the VMAC DTM70 installs up to 50% faster than other underdeck air compressors, as there are no modifications required to the RAM or Ford transfer case, no drive shafts required, and no additional components to be sourced. The new DTM70 for RAM is also tucked up under the truck, and does not change the truck’s ground clearance, another advantage against other underdeck systems.”

For a full list of DTM system applications and fitment and requirements, visit VMAC’s interactive application list: www.vmacair.com/application-lists. For more information on the DTM70, manufactured by VMAC, visit vmacair.com/DTM70.