Electric truck maker Orange EV expands to build more zero-emission 'yard dogs' in Kansas City

KANSAS CITY, Kansas—Almost 20 years ago, Kurt Neutgens failed to build an electric sports car company out of his garage. On Jan. 26, the governor was here to congratulate him and Orange EV co-founder Wayne Mathisen on opening a 440,000-sq.-ft. factory in her state so they can build thousands more electric yard trucks to help fleets cut emissions and improve depot operations.

No company in the U.S. has built more electric Class 8 trucks than Orange EV, which sold its first terminal tractor to DHL Supply Chain in 2015. The OEM delivered its 1,000th tractor to Lazer Logistics last November. Neutgens hopes to eventually double that output annually here in the Sunflower State.

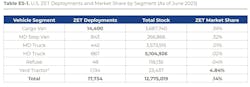

It’s a figure that no other heavy-duty truck maker comes close to. As of June, just 1,134 electric yard tractors were deployed in U.S. fleet operations, according to a 2024 study by Calstart. Another 867 heavy-duty, over-the-road EVs are operating nationwide, according to the same survey. But most of the more than 17,500 zero-emission supply chain vehicles operating today are light-duty cargo vans.

When companies look into decarbonizing fleet operations, a lot of the potential options aren’t readily available for over-the-road operations, Neutgens said as he sat across an unoccupied desk in a smells-like-new office just steps from his new 400-yard-long assembly line that can build five trucks per day. He envisions it eventually producing 2,000 EVs annually.

A dirty job

But the yard switchers are different. “These trucks are the dirtiest vehicles out there,” he said of the diesel-powered equipment designed to run for multiple shifts that make achieving Stage IV emissions difficult. “The emissions controls don’t really work for this application. It’s really dirty, and they work really hard. But you can solve both these problems at the same time. Our customers, if they are running two shifts over 10 years, will have an extra $500,000 in their pocket than their competitors with diesel. And it is not an exaggeration.”

According to Orange EV, its yard dogs offer fleets 90% fuel savings and more maintenance savings. Its trucks have no engine or transmission to service, no diesel regen cycle to maintain, and regenerative braking helps recharge the battery while saving wear and tear on brakes. Moderate use can save fleets up to $40,000 annually, while 24/7 operations can save up to $90,000 annually per EV truck.

Cold-chain fleet management company PLM Fleet is focusing more on zero-emission technology for reefer fleets. The company helps fleets meet capacity needs with equipment rental, leasing, and financing solutions. In its first fiscal year marketing Orange EV yard tractors, PLM has already placed 25 of the trucks in fleet customer operations.

“In the refrigeration and transportation space, PLM is the expert in all types of electric transportation,” Barry Steel, VP of PLM leasing programs, told FleetOwner. “The yard truck category is absolutely the best match for our customers.”

Track record

According to Orange EV, its terminal trucks have racked up more than 13 million miles and four million operating hours in the eight years since DHL added the first to its fleet. Over that time, the EVs reported 98% uptime, compared to the 75% industry average for diesel yard spotters. The first Orange EV DHL bought in 2015 is still operating today, and the LTL carrier now has 50 Orange EVs in operation at more than 30 locations.

“DHL saw enough potential in our very small company to order that first truck and continue to lead the industry recently announcing they intend to replace all their diesel yard trucks with Orange EV electric,” Mathisen, co-founder and chief executive, said before Friday’s ribbon-cutting ceremony.

DHL Supply Chain estimates that operating 50 electric yard trucks instead of diesel annually eliminates more than 2,500 tons of carbon dioxide, which, along with benefiting the environment, creates a healthier workplace for drivers.

While several EVs have been making headlines for struggling in the winter, Orange EV leaders note that their equipment has held up through harsh winters in Canada and Minnesota, one of 36 states where the electric yard retrievers operate. Unlike their diesel counterparts, there are no worries about fuel gelling in sub-freezing temperatures.

Because the upfront costs of the EV stevedores are more expensive than diesel equipment, PLM markets the equipment more like trailers than trucks. “You have to have a long-term outlook,” Steel explained. “So we’re able to put a really competitive structure together that makes it affordable for the clients. And it’s actually one of the easiest products to help somebody get started in fleet electrification.”

The right tool

An ACT Research study from earlier this decade found that electric yard trucks have a better TCO than diesels. A separate study by the North American Council for Freight Efficiency found that terminal tractors were “one of the best, if not the best, paths for heavy-duty tractor fleets to learn about and implement a BEV in a fleet operation.”

Since those two industry reports were released in 2022, the electric yard hostler fleet population has nearly doubled. Last year, they made up 4.8% of the fleet market, according to Calstart. All other commercial EVs made up 0.14% of fleet operations.

PLM’s Steel noted that a few years ago, fleets still worried about range anxiety, charge times, performance, and uptime. “There were so many questions that people had—but I think all the questions have been sufficiently answered already,” he said. “You’re going to really start to see this adoption accelerate dramatically. I’m feeling it already. I’ve got six trucks out on the line right now, ready to be delivered, that we’re going to look at later this afternoon. It’s jumping.”

The EVs need less maintenance, and Orange offers a 7.5-year battery warranty. Company officials stated that those first tractors sold in 2015 still operate with original battery packs. Steel also expects his clients to see an ROI much faster than with traditional equipment because charging is cheaper than diesel fuel.

Ribbon cutting

Governor Laura Kelly was among the dignitaries celebrating Orange EV’s expansion and move from Kansas City, Missouri, where it began, across the border to Kansas City, Kansas. It was a big moment for Neutgens, who two decades ago, was trying to find a way to make a difference in transportation.

After 17 years with Ford Motor Co., including time as the F-150 product engineering manager, Neutgens was offered a buyout in 2005 and wondered if he should take the opportunity to do something bigger. “Electric vehicles at Ford gave me an amazing education. They taught me so many things. They gave me skill sets that people dream about,” Neutgens told FleetOwner.

He had a passion for the environment and knew cars. “So I said, ‘I can do this.’ I tried to do an all-electric Mustang out of my garage and immediately failed. I spent my savings—all the money they gave me—for a year and a half and didn’t sell a vehicle. Because not very many people want to buy a car from Kurt’s garage.”

But he learned a lot—enough to get high-level jobs at companies working on electrification, such as electric airplane tuggers and cargo vans. But he was still looking for the next big thing.

“I did a great big math model of every vehicle I could think of,” Neutgens recalled. “I tried to estimate what it would cost to build it: what the batteries would cost; how many batteries we’d need; how big of a powertrain we’d need. I went from scooters to taxis to over-the-road trucking, garbage trucks to airport parking shuttles.”

While he saw some as good businesses to electrify, he also knew that his chance at market share would disappear the day legacy OEMs such as Ford offered an electric powertrain.

“I was kind of at the point where I thought I might not find it,” he said. “And one day, I was driving to work and saw a yard hustler—and I’d never seen one before. I literally pull off the road and drive up next to the guy at the Kellogg’s [distribution center] on the other side of the river.”

He hopped out of his car and ran up to the driver to ask him what he was operating. “He looked at me and told me to get off his lot,” Neutgens recalled. “So I was like, ‘Just tell me what this truck does because it looks interesting.’”

That led him to immerse himself in terminal tractors to see if he could electrify and build a business around them. He and Mathisen teamed up and found places in the Kansas City area to develop and test the technology.

Crossing the line

Mathisen and Neutgens finalized Orange EV’s move to Kansas after 10 years in Missouri.

“We founded and funded the company when the business was little more than an idea and a promise that we would work hard to see if we could build a mission-driven business that would positively impact climate change through a little-known piece of material handling equipment, sometimes called a yard truck.”

As Orange EV completes its move across the state line, it has more than 90 job openings at the large factory here in Kansas. The governor’s office noted that the truck maker is investing more than $37 million in the area, creating 185 new jobs, all for a little-known essential piece of heavy equipment.

“We make a vehicle that is not often in the public eye,” Neutgens said during Friday’s ceremony. “They’re called very many names—because no one knows what everybody else calls them. Yard hostlers, yard trucks, goats, mules, switchers, donkeys, horses, stevedores. But the one we love most is the yard dog. It’s loyal. It goes out, and it gets it, and it brings it back every time.”