Acrylic adhesives have long offered the advantages of increased cost efficiencies, better aesthetics and improved impact resistance compared to other methods for the assembly of complex structures. And recently, new acrylic technology has been developed that offers superior lap-shear strength, high elongation and high bake resistance combined with excellent failure mode across difficult-to-bond metal substrates. These “next-generation” acrylic adhesives are ideal for meeting the rigorous demands of the truck/trailer building industry.

But to appreciate the latest developments, a little background on the evolution of these adhesives is in order. Acrylic structural adhesives are two-component systems (adhesive plus accelerator) that deliver bond strengths that can approach or exceed the strength of substrates. Significant commercial use of acrylic adhesives began in the 1960s. “First-Generation” systems were known to be brittle and generally utilized for plastic bonding. They featured poly-methyl methacrylate dissolved in methyl methacrylate (“syrup”) and an accelerator “lacquer” used at a high mix ratio.

“Second-Generation” acrylic structural adhesives were developed in the 1980’s, and have delivered effective bonding performance in a variety of commercial applications over the last 30 or more years. These systems were tougher, and offered improved low-temperature performance and improved bonding to bare metals. They featured butadiene rubber tougheners, metal adhesion promoters, and 1:1 and 4:1 mix ratios with formulated accelerators

Next-generation acrylic adhesives have evolved to offer increased performance for more demanding applications, such as those found in truck/trailer structures. Key features of the next-generation adhesives include advanced terpolymer and core-shell rubber tougheners, blends of polymerizable monomers, and a 10:1 mix ratio. Enhanced performance characteristics that are of interest to truck/trailer builders include:

- High lap-shear strength – targeting structural bonding applications

- Improved peel strength – better performance for applications with mixed-mode stresses

- Outstanding failure mode across a wider variety of substrates – more robust performance increasing usability for multiple applications

- High impact-resistance – suitable for rugged applications where impacts may/will occur

- Improved fatigue resistance – holds up better under cyclic stresses or vibrations; and

- Excellent low-temperature performance – important for use in challenging climates

Resistance to e-coat, paint and powder-coat bakes – bonding parts will not shift/separate during bake process and will maintain high lap shear strength after bake.

Acrylic adhesives offer distinct advantages over metal joining techniques such as riveting or welding, most particularly in durability, fatigue resistance, distribution of stress, aesthetics, corrosion resistance, and process simplicity/cost. In the truck/trailer industry, acrylic adhesives have been used successfully in bonding applications to replace riveting and welding. Acrylic adhesives are also ideal for use in joining applications where mechanical fastening may not be feasible or practical, such as plastic and composite bonding.

Improved performance

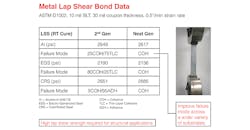

One important difference in physical properties between next-generation and second-generation acrylic adhesives is a significant increase in elongation (≥100-percent) while maintaining the same high tensile strength (≥18 MPa). This increase in elongation without loss of tensile strength is key to many of the elements in improved performance for next-generation acrylic adhesives.

Another element of improved performance for the next-generation acrylics, one that is most visible to fabricators, is the more robust performance across various, difficult to bond metal substrates.

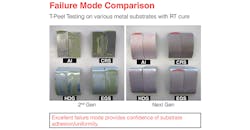

All things being equal, lap shear strength is primarily a reflection of the tensile strength of the adhesive, whereas good peel performance requires more toughness and elongation. The bonding results show equivalent lap shear strengths, while the more flexible next-generation adhesive demonstrates a clear improvement in the T-peel strength. The significant improvement in failure mode with the next-generation adhesive should also be noted.

For fabricators, confidence in adhesion is greatly enhanced by seeing good cohesive failure when bonded parts are separated, especially if there is an even distribution of adhesive between the two surfaces. Being able to achieve this good adhesion on multiple substrates with a single adhesive is also of great value, reducing complexity in assembly and reducing the risk of mistakes if forced to use multiple adhesives.

Figure 1 provides a visual comparison of the failure mode between different metal substrates bonded with a second-generation acrylic adhesive and a next-generation acrylic adhesive, with the samples pulled in T-peel. The consistent, uniform failure mode of the next-generation adhesive, when added to the impressive bond strength data, creates greater confidence in the robust performance of the adhesive.

Application: Utility truck bed assembly

In this application for the commercial vehicle market, a motivated manufacturer specifically redesigned their truck bed to accommodate use of adhesives as an assembly mechanism, gaining advantages in processing time, aesthetics and cost. A more flexible acrylic adhesive was targeted to provide the impact resistance needed for the demanding performance requirements of the dump-bed design. (See Figure 2.)

The previous dump-bed design required welding for assembly. However, welding is an expensive and time-consuming process, especially with non-ferrous or coated metals. Adhesives offer a much easier assembly method, requiring significantly less training and simpler equipment for application. Furthermore, bonded assemblies are more aesthetically pleasing, since they eliminate the unsightly weld deformations in the truck bed. With adhesives, the flat panels maintain a pristine and smooth cosmetic appearance with no weld marks.

Meeting the challenge

This truck bed manufacturer wanted the option of using one of three metal substrates—aluminum, galvanized steel, or Aluzinc (an aluminum-zinc-alloy-coated steel)—for fabricating the dump beds. Aluminum was desirable for its lightweight and corrosion resistant properties, but aluminum is also more difficult to weld. Galvanized steel can be more difficult to bond than aluminum, and many acrylic adhesives do not adhere or cure well on this coated metal. Aluzinc is even more challenging to bond, since this coating tends to cause variable bond performance even with the best of adhesives.

Ideally, the manufacturer was looking for one adhesive that could be used for bonding all three metal substrates, avoiding the complication of managing multiple adhesives in the assembly process. It was important that the adhesive did not release or delaminate even under extreme use conditions, including indentation and deformation of the dump-bed. Any adhesive used also had to be able to handle a high-temperature paint-bake process, which would be performed after assembly.

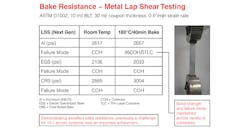

The next-generation acrylic adhesive was able to deliver excellent bond performance, with cohesive failure mode on all three metal substrates for the dump-bed application. The room-temperature-cured adhesive also demonstrated the ability to withstand the paint/powder-coat bake temperatures of 180 to 200 degrees C, without degrading the bond performance of the assembly.

Proof positive

Several tests were performed to prove the efficacy of the acrylic adhesive for the truck assembly process:

• Impact resistance testing – This test demonstrated that sharp impacts hard enough to cause deformation of the substrate did not cause brittle delamination of the adhesive, and that the subsequent failure mode in tear-down was 100-percent cohesive. The result proved that the frame could withstand the impact from heavy objects thrown into the truck without having the frame separate from the bed. (See Figure 3.)

• Bake resistance testing – This test demonstrated that the lap shear strength and the failure mode were not altered during the baking process. Figure 4 shows data for testing on various metal substrates in a 180 degrees C/40 minute paint bake.

• Environmental resistance – This test demonstrated that the adhesive bond performance remained robust under challenging environmental conditions. Since the vehicles must operate in all types of weather conditions, the adhesive performance must be designed to match. The next-generation acrylic adhesive was able to retain excellent bond strength on various metal substrates when exposed to environmental extremes. (See Figure 5.)

Application: Service truck body

For this application, another motivated manufacturer was looking to reduce weight and improve the assembly process, durability, and aesthetics in their truck bodies and truck beds. They wanted to accomplish these goals by switching to a lighter weight substrate for the truck bodies. However, the substrate, although lighter in weight, was more difficult to weld, so this manufacturer wanted to evaluate the use of adhesives for joining as an alternative to welding.

This manufacturer had some previous experience with adhesives, since they had been used successfully in the assembly of truck-body doors. However, the adhesive use had been limited to steel applications, and had not been attempted on lighter weight, less ductile materials. The company needed to be convinced that an adhesive could handle the stress loads of the truck chassis or withstand the high-bake finishing process.

Passing the tests

The company tested several types of adhesives, including next-generation acrylic adhesives. Some of the adhesives were too rigid and not flexible enough to maintain bonding strength. Although many of the adhesives met some of the design criteria, only a next-generation acrylic adhesive was able to meet all the requirements.

A torsion test was designed to prove whether the adhesive could hold up over an extended period of use/time, and if any stress cracks would develop in either the bond line or the assembly. Although one of the adhesive products tested did not fail bond-wise, it was so rigid that it eventually caused the development of stress cracks on the truck body. However, the next-generation acrylic adhesive was strong and flexible enough to hold up to the torsional twisting test without causing any collateral damage.

The next-generation acrylic adhesive also passed the high-bake test. While other adhesive candidates fell apart during the high-temperature e-coat process, the next-generation product maintained structural integrity without any degradation while going through the rigorous procedure.

Other advantages of using the next-generation acrylic adhesive were time- and labor-savings in the finishing process, compared to welding procedures. Once a piece has been welded by a skilled technician, significant additional labor and time go into grinding and sanding welds to achieve a smooth “finished” look. With the next-generation acrylic adhesive, which can be applied with simple manual or automated dispensing equipment, these grinding and sanding operations are eliminated, since the adhesive will not mar the outside of a finished piece.

(Contributor John E. Hill, PhD, is Principal Scientist, LORD Corporation)