Visitors to Mid-America Trucking Show view some potential future trailer technologies—along with new designs that are available right now

ADVANCEMENTS it trailer technology—some baby steps, others leaps of faith—were evident at this year’s Mid-America Trucking Show held March 27-29 in Louisville, Kentucky.

The 2014 edition of MATS featured exhibits by 1,077 companies and attracted more than 79,000 people from 43 states and 10 nations.

With heavy truck fuel economy standards now gaining the attention of regulators, weight savings and aerodynamics are more important than ever. These, along with corrosion resistance, operational flexibility were some of the key benefits that trailer manufacturers were emphasizing this year.

Several of these benefits were wrapped up in a futuristic trailer that Great Dane developed--a 53-foot van trailer made of full-length composite panels. The concept trailer was part of a commitment by Walmart to cut its fuel consumption in half over the course of 10 years, starting in 2005. The retailer is well on its way to achieving that goal. In eight years, the company has cut fuel consumption by 84%, primarily through operational changes. Walmart now is looking to tractor and trailer manufacturers to help the company achieve the remaining 16% reduction.

The trailer may be a concept vehicle, it is roadworthy. When the show was over, it left on a promotional tour that will take it across the country.

While the aerodynamic tractor and trailer promise to squeeze more miles out of a gallon of diesel, Walmart recognizes that achieving that goal will be the result of a wide range of changes, including repackaging goods to get more of them on the trailer, figuring ways to reduce overall fleet mileage, and taking a close look at every component on the tractor and trailer.

“We know there is no silver bullet,” Elizabeth Fretheim, director of business strategy and sustainability – logistics for Walmart said at a MATS press briefing. “But we are 84% of the way to our goal. We are looking for changes in tractors and trailers to get us the rest of the way.”

Among the novel features of the trailer is the use of carbon fiber for the skins of the panels that comprise the sidewalls.

“Carbon fiber can be wound on spools and woven like any other thread,” said Adam Hill, Great Dane’s vice-president of product and sales engineering. It’s expensive--$10 per pound vs less than a dollar a pound for steel. But it’s interesting how much the price of carbon fiber has dropped. It used to be $100 per pound.”

The walls use composite panels produced by Milliken and Fiber-Tech Industries. One key reason for using carbon fiber: The panels are only one-third the weight of conventional FRP panels. The roof, sides, and floors of the 53-foot trailer each consist of one-piece panels. Side panels are a made of carbon fiber skins and a composite core produced by Milliken. Carbon fiber also is used on the floor of the trailer—a single composite panel with balsa as the core.

While a substantial amount of engineering time went into the design, production of the trailer displayed at MATS went surprisingly quickly.

“We built it at our Terre Haute plant on a Saturday morning,” Hill said. “The panels are bonded with adhesives, and we used fasteners to hold everything in place until the adhesive cured.”

Advanced aerodynamic devices smooth airflow—including a custom faring mounted ahead of the landing gear. The faring connects the side skirts, resulting in a unified front to slash turbulence beneath the trailer.

Off-the shelf components used on the trailer include an SAF Holland PosiLift suspension that automatically lifts one axle when enough of the cargo has been unloaded, making the axle unnecessary.

Peterbilt produced the futuristic tractor that was coupled to the trailer. The custom cab has exceptionally little frontal area, with the only seat—mounted in the center—belonging to the driver. The look is more fighter jet than conventional truck cab.

A Capstone Turbine engine and an electrical powertrain team up to provide the power. Capstone Turbines specializes in microturbine power.

“The small turbine acts as a range extender,” said Capstone’s Steve Gillette. “The advantages include the ability for the truck to run on a variety of fuels with the same efficiency. And no SCR is required.”

New Eagle developed the software that helps the components to communicate with one another. Much of the communication is done wirelessly. www.greatdanetrailers.com

Also promoted at the Vanguard exhibit was the company’s bolt-together rear door frame. The design makes it possible to replace only the damaged portion of the frame, rather than the entire unit. It also simplifies changing between swing and roll-up doors should the customer desire a new door style. The bolt-together frame, which Vanguard tests indicate is stronger than welded designs, is expected to be made standard by the end of May. www.vanguardtrailer.com

The 53-inch-high upper hopper, made of 10-gauge steel, has a 96-inch by 193-inch opening. The single lower hopper is 59 inches by 118 inches and is made of ASTM A-572 steel. To maneuver over large piles, an oscillating fifth wheel pivots as needed. It comes with an 18-inch kingpin setting.

The XL Bottom Dump trailer will be available in late fall of 2014. www.xlspecializedtrailer.com

The XL 70 HDG is rated at 70,000 pounds overall and 60,000 pounds in 16-feet concentrated. The low-profile gooseneck saves weight versus traditional hydraulic necks, while its full-width design length of 10 feet, 6 inches and 49-inch fifthwheel height adds versatility.

The 29-foot long main deck has a loaded deck height of 18 inches with a six-inch ground clearance. Decking made of 1 1/8-inch aluminum extrusions makes the trailer lighter. www.xlspecializedtrailer.com

The product of a multi-year development project, the new Trail King All-Aluminum Center Frame Step Deck (TK80AACS) includes all-aluminum framing, armor-coated landing gear, and zinc-plated steel components as standards.

The AACS is expected to go into production later this year.

Trail King also displayed its new Hydraulic Sliding Axle (TK80SA) that features a cylinder that is completely retracted when the trailer is in the transport mode. It is designed for loading buses, road graders and rollers, all with one-man operation.

After starting small in Mitchell, South Dakota, Trail King is now a trailer manufacturer supported by a network of almost 400 dealer locations across the U.S. and Canada. The company’s trailers are sold in South America, Europe, Asia and other locations around the globe. Trail King has plants in Mitchell, South Dakota and West Fargo, North Dakota. The company has over 700 employees. www.trailking.com

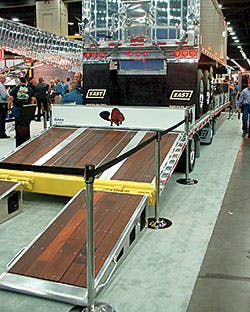

The strength of the drop deck trailer is the dual-T main beam and exclusive cross member design, which balances load stresses more evenly for longer life and less maintenance. Its two T-shape extrusion sections of 6061-T6 aluminum alloy are welded. Rather than bolted. The weld is along the neutral axis of the beam where stress is minimal.

Rated for 23,000-pound capacity per axle, the beavertail ramp section allows cargo to easily roll up onto the lower deck. The ramp section folds up to become part of the usable deck surface. Decks are available in all aluminum or wood.

The trailer comes standard with a Hendrickson HT250US air-ride suspension. Options include load scales for more accurate weighing of payload at the dock and the Hendrickson TIREMAAX Pro automatic tire inflation system.

East also announced the expansion of its aftermarket all makes parts and service program. The expanded program will provide all makes parts and service support across the United States and Canada through its network of more than 70 East authorized dealer locations. For faster service, East is establishing a new drop-ship program which permits parts to be shipped directly from the vendor.

East offers maintenance and repair services on-site for all makes and models of flatbed, drop deck, dump and refuse trailers to support the dealer network. Services are offered for trailers include wetline installation, wreck repair, body installation, brakes, alignment and more. East specializes in wreck repairs too large for most facilities at its service center at its Randolph, Ohio headquarters. www.eastmfg.com

The trailer design also incorporates a five-ride-height adjustable ratchet neck. This gives operators a total of five different ride heights on the gooseneck along with the ability to adjust the suspension height with Talbert’s plus-3 minus-3 leveling valve. The gooseneck is hydraulically operated and can be powered in either of two ways: through a PTO on the truck or a gasket mounted in the gooseneck. The trailer provides connections for both methods.

The trailer also is equipment with the Equalizer, Talbert’s trademarked nitrogen dampened axle extension that hydraulically transfers loads in all terrains. It allows a 14-foot 1-inch spread with 54-inch axle spacing or a 14-foot 7-inch spread with 60-inch axle spacing.

According to Doonan’s Mike Gordy, the company bought Chaparral in 2008 and has made more than 20 design changes that make the trailer lighter, stronger, and more corrosion resistant than its predecessor. www.doonan.com

About the Author

Bruce Sauer

Editor

Bruce Sauer has been writing about the truck trailer, truck body and truck equipment industries since joining Trailer/Body Builders as an associate editor in 1974. During his career at Trailer/Body Builders, he has served as the magazine's managing editor and executive editor before being named editor of the magazine in 1999. He holds a Bachelor of Journalism degree from the University of Texas at Austin.