Improving fabrication productivity

THE welding that goes into fabricating aluminum trailers, particularly tank trailers, offers an excellent opportunity to take advantage of any techniques that can speed up the process. These trailers often require multiple seam welds as long as 55 feet (16.8m) to join the aluminum panels that make up many of today’s over-the-road fleet.

Even though most long-seam welding these days is automated, the labor aspect of monitoring and controlling the welding process remains the largest variable in fabrication cost. By switching to larger diameter wire, manufacturers can weld more than twice as fast as standard production rates, but finding the right settings to achieve this high productivity can be tricky. We recently experimented with various sizes and speeds to provide guidance to the fabrication industry.

How we went for speed: Knowing the great cost saving potential in increasing travel speed, we set up a series of test butt welds to determine the best way to optimize welding productivity without sacrificing quality. That basically came down to finding the top travel speed that would still allow the equipment to get good penetration and produce a clean weld without spatter.

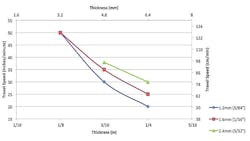

Using aluminum plates 1/8 inch (3.2mm), 3/16 inch (4.8mm), and 1/4 inch (6.4mm) thick and 5356 TM wire in three diameters – 3/64 inch (1.2mm), 1/16 inch (1.6mm) and 3/32 inch (2.4mm) – we produced 24 different test welds each roughly 8 feet long. We used mechanized welding equipment replicating the gantries commonly used in the industry.

By adjusting three variables – voltage, amperage, and wire-feed speed – we found the arrangement permitting the highest travel speed for each combination of plate thickness, electrode size, and welding mode.

Constant voltage, Power Mode, and pulse were the primary modes tested. We also used AC pulse mode, but only for two welds on 1/8 inch (3.2mm) material. All four modes are available on the power source used for these tests, a Lincoln Electric Power Wave R500.

Constant voltage is a common approach to welding control, where the wire-feed speed is also chosen and the current varies. The wire-feed speed dictates what the current flow will be; increase the wire feed speed and the current increases.

The opposite approach focuses on maintaining constant current and wire speed and allows the voltage to float. The third control method we used for the two heavier sizes of plate, Lincoln Electric’s Power Mode, simultaneously controls both the voltage and the current, while allowing the wire feed speed to remain constant. It makes much smaller adjustments and does so as much as five times faster than older equipment. The resulting improvement in arc stability and arc length are helpful in making the long welds so common in the trailer and body building field.

The surprising results

Increasing the electrode diameter allowed us to increase the travel speed quite a bit while maintaining weld quality, which was no surprise.

What did surprise us, however, was how much more productive we could be. As shown in the accompanying figure, going to a 3/32 inch wire from a 3/64 inch wire or 3/16 inch wire increased productivity from 20 percent to as much as 50 percent.

Naturally, for a given wire size there is a difference in maximum travel speed based on plate thickness. Thicker plates require a slower travel speed because the higher volume of material used in the operation requires more time and energy per unit length of weld.

However, for a given plate thickness: the larger the wire diameter, the faster the travel speed that can be used. The productivity increase is accomplished through careful configuration of the welding parameters, including an increase in amperage, to accommodate the larger wire.

Before setting up these tests we had observed field production rates as low as 12 ipm (30.5 cm/min) on ¼ inch (6.4mm) material. By carefully establishing and controlling the power settings, we were able to weld at 20 ipm (50.8 cm/min) using standard size wire, 3/64 inch (1.2mm).

Using larger wire provided even greater productivity. Again, on ¼ inch material and using the operating parameters we developed, increasing to 1/16 inch (1.6mm) wire enabled us to weld at 25 ipm (63.5 cm/min). Increasing to a 3/32 inch (2.4mm) electrode, the top travel speed went to 30 ipm (76.2 cm/min) – 50 percent faster than with the standard wire size.

In short, with a small investment in consumables and hardware, changing to larger diameter electrodes for long-seam welds can speed production and save fabrication costs. ♦