I’m admittedly a “trailer nerd,” my title even says so. I literally grew up in a business that was started in my family’s backyard just a couple of years before I was born. Today, my brother Jeffery and I both work in our family’s enterprise, and one thing we can both point to has been a part of this business from the start—the spirit of innovation.

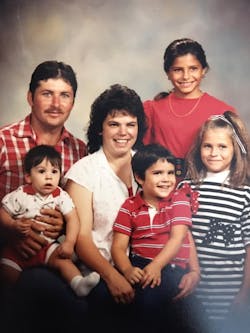

Founded in 1985 in the heart of East Texas by our parents, Kim and Mike Crabb, Diamond C was born out of necessity and a profound desire to make a meaningful impact. What began as a small family endeavor to support a personal livelihood has blossomed into a thriving business that focuses intensely on the well-being and success of our team members, customers, and community.

Our company’s tagline—“Do Work. Love Strong.”—encapsulates the ethos that has driven our family-owned company from its inception. Values of hard work, integrity, and community support are literally engineered into every trailer we build.

Innovation isn’t just about keeping up with the latest technology—it’s about pioneering it. At Diamond C Trailers, we work hard to be at the forefront of trailer design and functionality, pushing the industry towards newer, safer, and more efficient standards.

One of the clearest examples of our commitment to innovation is our adoption and advocacy of disc brake systems over traditional drum brakes, particularly for our heavier trailers in the 10K, 12K, and 16K weight classes.

The leap forward

Diamond C has carved out its niche in the trailer industry by consistently delivering reliable products coupled with exceptional service.

Our trailers aren’t just built—they are crafted with an attention to detail and a commitment to quality that we believe sets them apart in the marketplace. Our focus on quality and customer satisfaction is why we’ve leaned into developing and promoting advanced disc brake systems, which represent a significant leap forward in trailer safety and maintenance.

Historically, the trailer industry has relied heavily upon drum brakes, which are cheaper up front but offer less stopping power and require more maintenance over their lifespan. With electric drum brakes, the trailer often relies chiefly on the towing vehicle to provide the majority of the braking force, causing excess wear and tear and ultimately, expense. It’s not an ideal scenario.

Our exploration into disc brakes started from a simple yet powerful place: listening to our customers. Over the years, feedback consistently identified a demand for better stopping power and more durable, longer-lasting brakes. This customer feedback, coupled with advancements in brake technology, pointed to the idea that disc brakes were the next step forward for our trailers. While not new, disc brake technology has evolved significantly over the years, with improvements in electric over hydraulic pumps and the brake components themselves.

What began as a novel braking system for luxury and sports cars has today become standard equipment on virtually all passenger vehicles. Our move to prioritize the migration of disc brakes on trailers aligns with what we believe will be the ultimate adoption trajectory. Particularly for 10K, 12K, and 16K trailers—the benefits become even more pronounced, making disc brakes an essential feature for anyone requiring robust, reliable trailer braking performance.

Early challenges

Our initial switch to disc brakes was not without its challenges. Early on, we encountered issues with caliper durability and a constrained supply of replacement parts and pads, which was particularly pronounced with our first disc brake systems. This experience underscored the importance of quality components and reliable supplier relationships, which led our axle supplier, Lippert, to partner with a new disc brake supplier, DeeMaxx components.

Like us, DeeMaxx is a family-owned business. Its founder, Chuck Deegear, has worked in the trailer and disc brake industry for 30 years. He saw a need for new and improved brakes and spent countless hours developing what he called “the perfect trailer disc brake”. We were excited when Lippert informed us of their decision to go with DeeMaxx disc brakes.

Lippert’s transition to DeeMaxx marked a significant improvement; warranty claims and customer satisfaction issues related to disc brake components decreased dramatically. The superior grade of DeeMaxx’s components—from the quality of the brake pads to the unique coatings on the rotors—has made a substantial difference.

The DeeMaxx difference

DeeMaxx bills itself as the only brake manufacturer to pass the SAE J2681 Brake Test and to pass it “satisfactorily.” DeeMaxx has a trademarked integrated caliper mount-bolt/sleeve design for ease of installation and to ensure that they stay in place within the caliper. And DeeMaxx’s silicone boot also has improved performance at extreme temperatures compared to other designs.

Their patented rotor design runs cooler and has improved coating consistency. Water is able to drain and not collect in the hat section, and it has a larger diameter. DeeMaxx products also have more brake torque, which allows for shorter stopping distances and increased safety for all users. Other features that stand out are no warping on rotors; better caliper bleeding; exclusive laser writing on all calipers; no-handed component design; and compatibility with every surge and electric over hydraulic controller.

Read more: Felling Trailers chosen for very specialized trailer needs

DeeMaxx is also constantly innovating and providing customers, like us, with the benefits of its knowledge. The team at DeeMaxx make it their responsibility to provide exceptional customer service to us, ensuring our customer’s safety while using their trailer brakes, so they fit right into our philosophy.

Increasing interest

Our efforts are about creating a new level of trailer safety that encourages the industry to elevate its standards. Since its introduction, the adoption of the 16K disc brake has grown among our customer base, demonstrating the market’s recognition of its benefits and the strengthening demand for higher-performance braking solutions.

In our product lineup, disc brakes have increasingly become a factor. We now offer integrated disc brakes across our models from 7,000- to 16,000-lb axles, with the highest utilization on our 12K and 16K trailers.

These heavier trailers, which can range in price from $20,000 to $60,000, make the additional cost of disc brakes a relatively minor factor for our customers who prioritize performance and safety. While still an option on our 12K trailers, these trailers outfitted with disc brakes represent our highest volume in sales, indicating the growing preference among our customers for advanced braking systems.

Cost-benefit ratio

At Diamond C, our philosophy is that safety and quality should not be compromised for cost.

Disc brakes, while more expensive initially, provide superior stopping power, greater reliability under stress, and significantly lower long-term maintenance costs. Changing a set of pads on disc brakes is notably more cost-effective than replacing a complete electric brake assembly, as is required with drum brakes.

Despite the superiority of disc brakes, their adoption is taking time, with many manufacturers and customers entrenched in the traditional drum brake paradigm due to familiarity and initial cost savings. At Diamond C, we see it as our responsibility not just to innovate but also to educate.

We’re on a journey to familiarize the industry with the advantages of disc brakes, which is why I’m writing this article. From their enhanced safety to their reduced long-term maintenance costs, sooner or later, disc brakes are coming to a trailer near you.

Pioneering with purpose

In addition to being a trailer nerd, I’m also the chief brand officer at Diamond C. My role extends across many aspects of our business, from product design and marketing to sales and customer relations.

Decisions like the transition to disc brakes are aimed at advancing our brand and ensuring that every Diamond C trailer exceeds industry standards and customer expectations.

Our commitment to innovation isn’t just relegated to disc brakes; it’s illustrated through our pioneering efforts in other areas of trailer design, such as our move away from structural beams to custom-engineered I-beam construction on all of our gooseneck trailers.

Another example was our introduction of the low-profile, I-beam-frame dump trailer back in 2009. Other manufacturers took note of the design and today, virtually all dump trailers use I-beam frame construction.

Never-ending effort

Looking forward, our commitment to enhancing the trailer towing experience continues. We’re actively working with DeeMaxx and exploring further innovations with Hydrapro, focusing on the Electric-Over-Hydraulic (EOH) brake actuators.

These actuators are crucial for the performance of disc brakes, and recent developments have significantly improved engagement times and durability. Our goal is to enhance these systems to the point where disc brakes can become a standard feature across more of our models, balancing cost reduction with advanced technology to make this option accessible at all levels.

By continuing to work on cutting-edge developments in brakes, axles, lighting, and other critical components, we ensure that our trailers not only meet but exceed the expectations of our customers. Our journey with disc brakes is more than a simple switch in technology—it’s a reflection of our broader commitment to quality, innovation, and customer satisfaction. As we continue to innovate, we remain dedicated to the principles that have guided us from the beginning: to build extraordinary trailers and provide unmatched service, ensuring the growth and success of our community and everyone who comes into contact with our products.

About the Author

Jacob Crabb

Jacob Crabb, trailer nerd, chief brand officer and partner at Diamond C Trailers, represents homegrown expertise in the trailer industry. Immersed in his family’s company from a young age, Crabb has garnered experience across various facets of the trailer business, from manual labor to marketing management. Crabb’s journey through every department not only highlights his deep connection to the trailer business, but also his commitment to helping to steer the industry toward continuous innovation and growth.