Hannover, Germany. Imagine a combination of the Mid-America Trucking Show and the Work Truck Show, along with a bus and coach show and a parking lot full of aerials, throw in a job fair, and then multiply all of that several times over and you’d have the biennial IAA Commercial Vehicles show.

For the week-long 67th IAA, more than 2,000 journalists from 54 countries were accredited by the Sept. 19 Press Day preview. This year’s theme, Driving Tomorrow, focused on the question of how transport and logistics can be made even more efficient, greener and smarter.

And while some a of the equipment brands highlighted in the following IAA coverage might not be familiar in North America, these products will certainly spark a sense of familiarity—and maybe even ignite a fresh idea or two.

Daimler emphasizes ‘holistic’ solutions

The day before IAA officially opened, the world’s largest commercial vehicle manufacturer hosted about 500 international media representatives and provided the opportunity to personally test the complete range of current trucks, buses and vans from Daimler. This “Product Experience” took place in and around Hangar 1 at Hanover Airport. Where aircraft normally take off and land, about 40 commercial vehicles were presented and tested. From pickups to all-electric city buses and trucks to partially-automated long-distance trucks—everything was on display.

“We don’t just talk about innovations, we deliver them,” said Martin Daum, member of the board of management of Daimler AG responsible for Daimler Trucks & Buses. “That’s exactly what our participation in IAA Commercial Vehicles is all about. We offer our customers concrete products and solutions with clear customer benefits, especially in the trend areas of electric, automated and connected driving.”

New Sprinter

With an emphasis on versatility, Daimler’s Product Experience prominently featured the new Sprinter commercial van, the global bestseller among large vans. Whether panel van, tourer or chassis, front-wheel, rear-wheel or all-wheel drive, low-emission diesel engine, all-electric or as Concept Sprinter F-CELL with fuel-cell drive—”the Sprinter has the answer to all of today’s and tomorrow’s questions,” as the company explained in a number of presentations at this year’s show.

“The rise of the internet leads to a new business environment with new possibilities,” said Wilfried Porth of Mercedes-Benz Vans, a member of the board of management of Daimler AG. And the demands of an evolving supply chain call for “holistic solutions” such as the new Sprinter, a vehicle that now integrates “connectivity, innovative hardware and software solutions, and new mobility concepts.”

Speaking a day later at the Mercedes-Benz Vans press conference at IAA, Klaus Maier, head of sales and marketing, called the original Sprinter “the first van of a new species,” and likened the shift it generated in the van market to the introduction of the smart phone.

“How could we live without it?” he said.

And the new Sprinter, designed around “modular principles,” is “more versatile than ever before,” Maier added.

Indeed, more than 1,700 different Sprinter variants can be generated by combining body styles, powertrain configurations, cab designs, body lengths, tonnages and cargo space heights. This versatility makes the new Sprinter the vehicle of choice for a wide range of transport needs and sectors (and a flexible platform for upfitters), whether as a construction site vehicle, a van for parcel delivery services, a vehicle for service technicians or a VIP shuttle.

With rear-wheel drive, the new Sprinter covers a tonnage range between 3.0 metric tons (6,600 lbs) and 5.5 metric tons (12,1253 lbs) gross vehicle weight. Including the maximum trailer load, the gross combination weight increases to up to 8.75 metric tons (19,300 lbs) for the semitrailer tractor. The tractor head variant of the Sprinter is available only to body builders. In combination with front-wheel drive, this allows maximum freedom in the design and use of bodies.

The wide range of engines with outputs between 84 kW (114 hp) and 140 kW (190 hp) are available.

But in addition to the traditional diesel options, Daimler also showed off the Mercedes-Benz eSprinter, a fully electric large van that premiered in February. A battery capacity of 55 kWh makes for an anticipated range of around 150 kilometers (93 miles) with a maximum payload of 900 kg (2,000 lbs). With the second battery option customers can set other priorities. Batteries with a capacity of 41 kWh allow a range of around 115 km (71 miles), while the maximum payload in this case increases to 1040 kg (2,300 lbs). The electric drive system in the eSprinter has an output of 85 kW (116 hp). Its top speed can be configured to a maximum of 80 km/h (50 mph), 100 km/h (62 mph) or 120 km/h (75 mph). The eSprinter is due to be launched in 2019.

Additionally, Mercedes-Benz Vans provided insight into the future of locally emission-free mobility with the Concept Sprinter F-CELL, showing how the advantages of a short charging time, a low system weight and long range with the hydrogen fuel cell can be combined in a camper van.

Beyond the hardware, the new Sprinter is “a fully connected van that is much more than just a vehicle,” Porth continued. A wide range of services have been grouped together by Mercedes-Benz Vans under the brand name Mercedes PRO. Mercedes PRO starts with the professional connectivity and fleet solutions of Mercedes PRO connect, the networking of fleet managers with their vehicles.

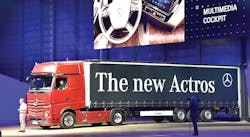

New Actros

“The future is here,” said Stefan Buchner, head of Mercedes-Benz Trucks, as he emerged from the new Mercedes-Benz Actros, which incorporates numerous features from the conceptual Future Truck introduced in 2014.

The rollout of the Actros, the brand’s flagship highway tractor, included several “world premieres”—important for North American trucking fleets because anything debuting at IAA is likely coming across the pond in the near future.

The new Actros includes active drive assist, which “gives the driver access to semi-automated driving at all speeds for the first time in a series production truck,” Daimler said. It can apply full emergency braking up to a speed of about 32 mph.

Another new feature is MirrorCam, based on concepts first seen on the Future Truck. The system, which replaces traditional side mirrors, offers a wider range of vision and background illumination to adjust for poor lighting.

Inside the cab, there is also a multimedia cockpit display aimed at simplifying the business and infotainment options a truck driver often accesses while in motion.

Schmitz Cargobull sets global goals

Europe’s largest trailer builder, Germany-based Schmitz Cargobull, wants to be the world #1.

Under its Strategy 2025, Schmitz Cargobull is aiming to become the global market leader for box semi-trailers and platform semi-trailers, as well as the European market leader for tipper trailers, explained Andreas Schmitz, chairman of the Schmitz Cargobull AG board of management during the company’s IAA press conference.

To achieve these goals, Schmitz Cargobull will be pursuing three main avenues: First, to expand business by increasing its market share in established markets; second, to expand on geographical scale using existing products; and third, to develop new products close to its existing portfolio for the European market.

For the current financial year, the company plans to produce around 67,000 vehicles and generate revenue of 2.4 billion euro ($2.8 billion) Schmitz noted. Another major goal is to increase its profit margin to 4.8%—but the company is facing many of the same challenges currently present in the North American trailer market.

“Following the rise in commodity prices, material costs and energy rates, we failed to reach our profit targets for 2017/2018, despite the introduction of price adjustments,” Schmitz said. To battle the trend of rising costs, purchasing will pursue global sourcing on “a more rigorous basis.”

Likewise, strategic expansion in its multinational manufacturing footprint in underway. The company, which employs 6,400 people worldwide, has added capacity at its box trailer plants in Vreden, Germany and Panevežys, Lithuania. In addition to multiple facilities in Germany, the Schmitz Cargobull also has plants in Russia, Turkey, and Spain.

And, like leading North American trailer manufacturers and industry suppliers, Schmitz Cargobull is focusing on connectivity and telematics.

“We are experiencing strong growth in our service divisions. With the new generation of our TrailerConnect trailer telematics system, we are already able to offer our customers the infrastructure needed for future communication with data transmitters on transported freight,” Schmitz said. “This means that our trailers are already ‘digital ready’ and prepared for the future of transport logistics.”

As well as improving the efficiency of production processes, products and value added services, the company is also looking at new “disruptive” business models, while working with customers to create solutions for digitalizing fleet management and logistics processes. To develop these technologies, the company has launched its own tech startup, and acquired another.

“Our extensive range of services and comprehensive infrastructure provide us with a solid basis for transparent, low running costs over the entire product life-cycle,” Schmitz said. “With over 35,000 active telematics systems, 1,700 Service Partners across Europe, over 68,000 spare parts available within 24 hours, and more than 3,500 Full Service contracts signed last year, there is more than enough evidence that we are already on the right track.”

AL-KO offers trailer control system

AL-KO is making its Trailer Control anti-skid system available for commercial trailers and adding new technology, including the AL-KO 2LINK connectivity system with tire pressure monitoring.

As introduced at IAA, the AL-KO Trailer Control (ATC) system is designed to lessen the effect of “evasive” maneuvers, bridge cross winds and wind pressure on trailers by “quickly and gently” braking the trailer and putting it back on track.

The company said its emergency system has been proven in camping trailers for more than 10 years, with nearly 200,000 installations in Europe, where ATC already is standard equipment for many manufacturers. Various ATC versions are tailored to the total weight on the trailer, from 750 kg (1,653 lbs) to 2,800 kg (6,173 lbs).

The system permanently controls the behavior of the trailer. Sensors detect the slightest lateral movements and lateral accelerations before a stabilization program in the towing vehicle can register the oscillating movement. In critical driving situations that cause the trailer to roll, the ATC control electronics react automatically, AL-KO said.

If the characteristic oscillation periods and vibration curves occur, the trailer brake is immediately activated by a servomotor and the trailer gently brakes. Braking power of a few seconds is enough to stretch vehicle and trailer and restore safe driving conditions, AL-KO said. Since the ATC sits directly on the axle and acts via the brake linkage, no intervention in the overrun device is required. The ATC sensors, the control electronics and the servo motor for the brake intervention are housed in a compact, splash-proof housing. It is permanently mounted on the axle, coupled to the trailer brake and connected to the existing on-board electrical system of the trailer.

The new 2LINK connectivity system complements ATC, and will include a Tire Pressure Monitoring System (TPMS) starting in November, the company said, with the information displayed on a smart phone.

Volvo Trucks going electric next year

Volvo Trucks will begin selling electric trucks in Europe next year, and at IAA the Swedish truck manufacturer put the Volvo FE Electric on display. The model is a waste disposal truck with a body that has been built in collaboration with Faun, Europe’s leading manufacturer of refuse truck bodies. It has a gross weight of 27 tons.

Electric trucks are much quieter and cleaner than their diesel-engined counterparts and open up new opportunities in the field of logistics. “Electric mobility is an important part of our long-term commitment to sustainable urban development and zero emissions,” says Claes Nilsson, president of Volvo Trucks.

StreetScooter

StreetScooter is a pioneer in new e-mobility and market leader for electric commercial vehicles in Germany. More than 7,000 StreetScooters are already in use by Deutsche Post for delivery services, and they have already driven more than 35 million km (22 million miles), while saving 23,000 metric tons of CO2 each year.

The WORK L Cool made its debut at the IAA. This electric vehicle will be mass-produced in the future and will be able to handle a payload of up to 600 kg (1,323 lbs). The refrigerated body is perfect for transporting perishables at consistently low temperatures, emi ssion-free and whisper-quiet. The all-electric refrigerated truck is based on the WORK L model and can be operated with either active or passive refrigeration technology. The cooling operates via an independent power supply, that way not affecting the mileage the truck can cover.

In addition, StreetScooter’s stand featured the wide variety of body options for the WORK and WORK L models. The WORK L with a 3-way tipper body and integrated tool box is a versatile all-round tool for public services and tradespeople alike. Whether it’s a parks and gardens department, a building and civil engineering team, or trade professionals: They all make a noticeable contribution to sustainable climate protection with the zero-emission engine.

Humbaur

Exhibits which Humbaur is displayed for the first time at IAA included a FlexBox Freeze freezer body fitted to a MAN TGL HGV chassis. The vehicle is equipped with a stainless steel rear portal and a Bär liftgate. It features a Carrier Supra refrigeration unit with Prevention Service monitoring module; internal equipment includes a baffle circulation wall and a cold curtain at the rear. Stainless steel track rails allow cargo to be secured, while the floor features an aluminum Gripster layer instead of anti-slip flooring. The rounded corners of the body not only look sleek and modern, they also enhance the vehicle’s aerodynamics and help to reduce fuel usage.

Also on display was a Humbaur concept vehicle in the form of a pharmaceutical body based on the StreetScooter electric vehicle. The PurLight GFRP lightweight construction conserves the vehicle’s battery charge, thereby increasing the range. The box body measures 1920 x 1650 x 1270 mm inside and allows the transport of about 350 kg payload. The loading volume corresponds to 60 E2 boxes. The pharmaceutical box body has an ATP certificate and is equipped with side doors on the left and right. The Thermo King B100 cooling unit has a stand cooling system as well as a heating system to ensure the transport of pharmaceutical goods within the prescribed temperature range.

Kögel

Making its debut at IAA, the Kögel Port 45 Triplex weighs in at just 4,480 kg in its basic form, with a technical gross tare weight of 41,000 kg and a fifth-wheel load of 14,000 kg. The chassis is ideal for transporting 20, 30, 40 and 45’ ISO containers as well as 40 and 45’ Highcube containers. The new Port 45 Triplex is currently one of the lightest container chassis on the market. This allows payloads of over 36,520 kg, guaranteeing maximum cost effectiveness for intermodal transport. The tare weight of the basic chassis can be trimmed still further with weight-saving individual equipment such as aluminium wheel rims and an aluminium compressed air reservoir.

The completely redesigned Kögel Lightplus Coil celebrated another premiere at IAA. The lightweight semi-trailer for transporting coils and split strips also has the optimized external frame profile and improved body that characterize the Kögel NOVUM generation trailers. With a low tare weight from 5,420 kg with customized equipment and 5,790 kg in the standard version, it is designed to be exceptionally cost-effective to drive. The technical gross weight is 39,000 kg and the technical fifth-wheel load is 12,000 kg.

Kässbohrer

Kässbohrer continues to extend Europe’s widest product range: from curtainsiders to tanks and silos, from low-beds and low-loaders to platform-semi-trailers. Pictured above, Kässbohrer’s Curtainsider swap body K. SWAU C.

Krone

AT the IAA 2018, Krone presented its Smart Scan load compartment detection system. Load capacities are detected and better used thanks to its intelligent load space detection. With Krone Smart Scan, dispatchers receive fast and reliable information about exactly where loading capacity is available on the vehicle. The Krone load space detection system presented in 2016 has since been optimized and enables digital support and intelligent load space detection by means of camera and sensors. The system was awarded the “Trailer Award” in the “Smart Trailer” category.

Also from Krone, the electric KEP shuttle is designed to conquer the last mile. Around 3.2 billion parcels are shipped and delivered in Germany every year and the number is growing. More city-friendly delivery vehicles are in demand, so Krone combines its integral bodies with various chassis.

The main features of the delivery-friendly KEP vehicle include a passage door from the driver’s cab to the cargo area; double-wing rear door; rear step with integrated anti-slip protection; loading space with 2 rows of shelves each left and right; and anti-slip mats and load securing certificate.

Ford Trucks

The Ford Trucks F-Vision – Future Truck is not your father’s Ford pickup, and it drew quite a crowd to the Ford Otosan booth (Ford’s truck unit in Turkey) at IAA.

The fully electrically-powered F-Vision is the first concept truck from Ford Trucks. This is the prototype of a level 4 autonomous truck. The concept model reveals Ford Trucks’ future vision on electrification, autonomous and connected drive, lightweight and zero carbon emission products. It’s designed to attend to humans’ priorities both inside the cab and on the road, as well as for the load being carried, and aims constantly to connect and communicate with the environment and users.