Latest from Distributors, Upfitters

This is the second installment of the Back to Basic Series, based on workshops presented by the National Truck Equipment Association. Certification basics were covered in the first installment.

Marriages work best when the two parties are compatible. The same holds true for putting together commercial trucks.

Whether the customer has a truck body and needs a chassis, or if he already has a chassis and needs a truck body, the truck equipment distributor is responsible for performing the marriage. And if he doesn't want his customer to divorce him, he will make sure that the commercial truck he is bringing together consists of products that are made for one another.

Marriages sometimes face problems when at least one of the parties is overweight, overloaded, or imbalanced. Trucks, however, do not need to suffer from the same conditions if chassis, bodies, and equipment are well matched before they are brought together. Properly specified trucks may not live happily ever after, but they at least should last long enough to be fully depreciated.

To make the right choice, you need to know what to look for and what is important. The criteria people use for selecting a mate is pretty subjective,but matching up the components for a commercial truck is fairly straightforward. It is a matter of knowing basic terms, key specifications, and simple formulas. For human beings, the process isn't as easy. Try finding the ideal marriage partner by crunching numbers.

When looking for the perfect chassis consider:

• Gross axle weight ratings (GAWR). How much weight can be placed on the front axle or the rear axle?

• Its gross vehicle weight rating (GVWR). This is how much the truck will be allowed to weigh when all the equipment is mounted and it is fully loaded. The GVWR cannot exceed the total of all the GAWRs.

• Tare weight. How much does the chassis weigh before the body and equipment are installed? Front and rear bare chassis weight includes the weight of all options, fuel, lubricants, and coolant.

• Cab-to-axle (CA) dimension. The distance from the back of the cab to the centerline of the rear axle, this dimension helps determine the length of body that can be mounted on the chassis. A similar concept for tandem-axle trucks is the CT dimension, measured from the rear of the cab to the centerline of the tandem.

• Wheelbase. The distance between the front axle and the rear axle (or the centerline of tandem axles) affects body installation, truck performance, and whether a particular axle is overloaded.

• Cab to body (CB) is the distance between the truck cab and the body.

• Body length (BL) is the distance from the foremost point of the body to the rearmost point of the body.

Putting Them to Work

The above concepts can be used in simple math formulas to select bodies and chassis. The answers obtained by using these formulas are close but not exact. The formulas assume water level loads and locate the center of gravity for the body and load at the center of the body.

The following formula should be used when you have a chassis and want to select the proper body length to match the chassis.

Body length equals:

Where: GAWR.R is the gross axle weight rating for the rear axle. CWR is the amount of the curb weight on the rear axle. WB is the wheelbase of the truck. GVWR is the gross vehicle weight rating of the truck. CW is curb weight of the truck. CA is the distance between the rear of the cab and the rear axle. CB is the distance between the cab and front of the body.

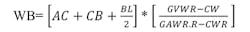

When you have a body and want to select the proper chassis wheelbase to match the body, utilize the following formula:

WB=wheelbase AC=front axle to back of cab CB=cab to body clearance BL=body length CW=chassis curb weight CWR=chassis curb weight (rear) GAWR.R=Gross axle weight rating (rear)

The following formula should be utilized when you have a body and want to select the proper cab-to-axle to match the body.

Spreading the Weight Around

When people overeat, the weight tends to collect around the middle. For trucks, it's okay to have most of the weight there.

As a general rule, approximately 60-70% of the body should be forward of the center of the rear axle(s). This percentage can be adjusted several ways. Moving the center of gravity forward places more load on the front axle. Likewise, a move rearward removes weight from the front axle and places it on the rear.

Under no circumstances should the weight exceed the rating of any axle. Nor should the vehicle weigh more than its GVWR when the body, equipment, and allowable payload are included.

Just like people, overweight trucks have to work harder and wear out faster. But unlike people, overweight trucks are illegal and can be fined.

Maximum Net Payload

A truck is built to carry more than its own weight. It also must carry the weight of the body and/or equipment installed on it, along with payload and passengers. Furthermore, a truck should not be so loaded down with equipment that it does not have adequate payload capacity for its intended function.

GAWRs are determined by considering the capacity of each component in the system, including tires, brakes, wheels, suspension, and axle assembly. The capacity of the weakest link in the chain-the component with the lowest rated capacity-is the GAWR. GVWR, in turn, cannot exceed the capacity of the individual axle ratings.

By knowing the GVWR of the truck, it is possible to determine how much the truck can carry. The GVWR can be found in the GVWR selector chart in the model section of a truck data book, in the incomplete vehicle document, and on the certification label.

The next step is to determine the curb weight of the model and add that to the combined weights of the driver, passengers, truck body, and/or equipment. (The standard weight for passengers and drivers is 150 lb) The sum of these weights is then subtracted from the GVWR to obtain the maximum allowable (net) payload.

After the maximum net payload is determined, a weight distribution calculation must be performed to ensure that the individual axle loads do not exceed the GAWRs and governmental weight laws and restrictions.

Center of Gravity

How the truck performs when braking, as well as its ability to meet some Federal Motor Vehicle Safety Standards is affected by its center of gravity. The center of gravity (CG) is the point at which the weight of the chassis, body/equipment, and payload (if collectively or individually supported) would balance vertically, horizontally, and laterally.

The weight of the body along with attached equipment and their CG locations (both horizontally and vertically), as well as the positioning of the cargo load, are important to the stability and handling of the completed vehicle.

When calculating the CG, the first step is to establish the reference points for the horizontal, vertical, and lateral center of gravity measurements. Typically the horizontal CG is measured in relation to its distance from the front axle. If the front axle is used, measurements forward of the front axle are negative. If the CG of an unmounted body is being calculated, any point such as the front wall can be used.

The vertical CG for a chassis can be measured from either the ground or the top of the frame rail at the back of the cab for compliance calculations. If the CG of an unmounted body is being calculated, any point such as the bottom of the long sills can be used.

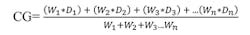

The basic formula for CG is the sum of the weight times the distance from the reference point for each component divided by the total weight of all components. This is the basic formula:

CG= Center of Gravity W= Weight of Component D= Distance from Reference Point n= Last item

The vertical chassis CG is included in the incomplete vehicle document provided by the chassis manufacturer. All CG requirements as stated by the incomplete vehicle manufacturer must be followed in order to assure compliance to all applicable Federal Motor Vehicle Safety Standards.

Bridge Formula

The purpose of the Bridge Gross Weight Formula (Bridge Formula) is to provide a standard for controlling truck weight by the number of axles and axle spacing in vehicles that use highway bridges. The bridge formula is used by the federal government to control truck weight on the Interstate Highway System. It is also used by states to regulate truck weights on state-controlled highways.

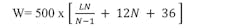

W=500 x LN + 12N + 36 N-1 W= the maximum weight in pounds that can be carried on a group of two or more axles to the nearest 500 lb.

L= spacing in feet between the outer axles of any two or more consecutive axles. N= number of axles considered.

The weight limit for two axles with a spacing over eight feet and under nine feet is 38,000 lb. As the number of axles and the axle spacing is increased, the Bridge Formula allows more weight to be carried. For example, at nine feet spacing, the weight limit for two axles is 39,000 lb. But three axles with an extreme spacing of 97 inches (more than eight feet) can carry a load of 42,000 lb.

According to federal law, two or more consecutive axles may not exceed the weight computed with the Bridge Formula even though the single axles, tandem axles, and gross weights are within legal requirements. All combinations of axles on a vehicle must be within the bridge formula limits.

Prior to checking axle combinations, make sure that single, tandem, and gross weight limits are satisfied.