THERE will be strong trailer demand above replacement levels for the next five years because the key drivers all remain positive, according to Dick Giromini, president & CEO of Wabash National.

In his presentation, “A Trailer OEM’s Perspective on the CV Market,” Giromini said manufacturing activity and retail sales are driving freight volume.

“Housing starts drove some volume, but they haven’t been a mover like they were in previous cycles yet,” he said. “Some people may actually look at it as good news: ‘With the amount of demand we already have, and housing hasn’t fully recovered, that’s just more demand in the future for us.’

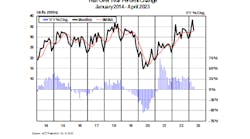

“Truck tonnage is at or near record levels. This is good news for both fleets and OEMs. Truck loadings continue to rise. That’s pretty much in parallel with what we’ve seen with truck tonnage. But while it’s true that the growth rate divergence became apparent around 2008 as related to improved freight density driven by product and packaging optimization, we still see strong growth in loadings.”

Trailer demand drivers as they relate to carrier capacity and rates:

• Active truck utilization has reached 99%, and is expected to stay elevated.

• Truckload rates are increasing. “And despite an increasingly tougher operating environment driven by increased regulation, many carriers delivered net profit margins exceeding the previous peak: 5%-6%. That’s important. That’s how many of the fleets have performed in what is a tough environment, and they’re operating very well. They’ve taken advantage of technology and optimized their business, and are doing better than many realize. As a result, many are ready to make investments in new equipment.”

• Driver shortage and pay increases. “It could create short- term headwinds to profitability. One large fleet executive made a comment, ‘This time, it’s real.” We’re hearing about raising pay for drivers, but currently the environment is strong enough that they’re also able to get rate increases.”

Fleet equipment/trailers:

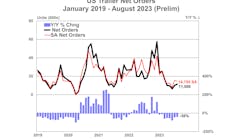

• The average age of equipment remains near the record high of about 8.1 years. “Fleets will continue to replace aged equipment to improve equipment utilization uptime and keep maintenance costs down. US trailer production from 1998-2000 made up the three consecutive strongest years of trailer demand in history: 863,000 were produced and sold in those three years, with dry van being 60% of all equipment.”

• Three-plus years of significant under-buy (2008–2010), with only 350,000 built and sold. “That’s an over-500,000-unit difference for the target population that would have been targeted for replacement, and only a small percentage got replaced. It’s still estimated there could be as many as 300,000 in the system that need to get out. They’re getting older by the day. We’re thinking of ‘98 trailers that may be in the system. That trailer is 15, 16 years old. It’s a teenager. Trailer equipment is very much the same as teenagers.

The uptime decreases. It’s in the shop more. All of that is causing operating cost per mile to increase, and also the ability to meet demands of shippers and commitments on delivery times. This aged profile, as I like to refer to it, is very sporadic, with peaks and valleys.”

Regulatory:

• Heavy-Duty Tractor-Trailer Greenhouse Gas (HD GHG). “There’s a lot of chatter about what is going to be considered to be included in that realm. The word we’re hearing is trailer performance requirements are going to be included. They got excluded the last round. That could end up driving up costs for fleets. That’s not a good thing.”

• California Air Resources Board (CARB). “That has driven a lot of the mandatory adoption of side skirts and side fairings on trailers. As time went on and the cost of a gallon of diesel fuel hovered around $5, it became cost effective for fleets to adopt these side skirts as an immediate way to gain improvements in fuel economy in the 4-6% range.”

• Compliance, Safety, Accountability (CSA). “It has really changed behaviors, which is driving demand. Prior to 2010, fleets were not subject to public reporting of the road worthiness of equipment. Prior to now, I would hear that tractors would attract and retain drivers. With the advent of CSA, drivers now don’t want to be subjected to the high risk of driving old equipment subject to burnt-out lights and other things. It’s actually an attraction and retention tool to have late-model trailers. On top of that, insurance rates are higher on fleets with lower ratings. Some shippers won’t do business or won’t pay as much because they say they’re accepting a higher risk. CSA has had more impact than what meets the eye.”

• Hours of Service (HOS). “We’ve heard about the impact on productivity.”

• Moving Ahead for Progress in the 21st Century Act (MAP-21). “That’s what I like to refer to as the lengths, weights, and combination study. This is like the third time they’ve done it, and it keeps getting kicked down the road. We’re hearing that the 33-foot trailer piece of it has a level of support that could very well get adopted. It’s not going to affect weights. It’s actually going to improve congestion on highways. There is some momentum for that to go from 28-foot doubles to 33-foot doubles. You get equipment out of the system and a little more compact look.”

Giromini said he feels trailer demand will be somewhat stronger than what is being reflected in FTR’s numbers, and that’s partially based on the “assumed approval” of 33-foot legislation in 2016, 2017, and beyond.

He said Wabash has a responsibility to lower operating costs and enhance productivity.

“As a leading manufacturer, Wabash National feels we have a responsibility to make customers more successful and more profitable,” he said. “This is why we do what we do. It drives our manufacturing footprint, our manufacturing initiatives, our R&D and product development and trailer technologies. We want to optimize weight, cube, and payload capacity, extend the life of the equipment, and continually enhance product safety and sustainability.”

When and how do fleets decide it’s time to trade in equipment and purchase new trailers?

“The ultimate decision comes down to lower operating costs,” he said. “When a trailer gets too expensive to maintain and run efficiently, it needs to be replaced. That’s based on individual fleets’ financial assessment that fits the operating strategy. Some fleets believe the best thing for them is trading trailers when they’re still young. They get good profit on a sale, put new equipment on the fleet, and attract and retain drivers. That keeps their maintenance down. Then there are other fleets that believe in getting the most out of their equipment that they can: ‘I’m going to extend the life as much as I can and when it gets painful, then I’ll trade it in.’ ” ♦