Leyman SLP provides large steel platform

Leyman Lift Gates announces the introduction of the new heavy-duty large steel platform on SLP Heavy Duty Hide-A-Way (Tuck-Under-style) liftgates. The SLP has minimum floor heights of 36" and 44" that allow the platform to offer a level ride at all bed heights. The SLP Hide-A-Way will come standard with platform sizes of 80" × 50" and 52", and it will help simplify loading and unloading.

The company says it has the only gate with four springs to allow for a larger platform. Spring assistance with the primary and secondary platform enables the operator to open and close the gate with less effort and physical exertion.

SLP Hide-A-Way models are available with lifting capacities of 2,500 and 3,500 lb and are shipped completely assembled with a heavy-duty platform extension. This liftgate is low-maintenance, featuring greaseless bushings at major pivot points with chrome-plated pins to add years of operational life. The SLP Hide-A-Way also has low psi due to a large cylinder surface. The power unit has thermal protection for the motor. Motor and pump are enclosed in a steel power unit box that keeps them protected from the elements year-round.

E-mail [email protected] for additional information.

SEMS simplifies snowplow powering

Parker Chelsea introduced its new SEMS (stored energy management system) for light- and medium-duty snowplow trucks at the NTEA Work Truck Show in Atlanta. It combines a new electronic-over-hydraulic control system with a PTO-mounted pump and an accumulator to eliminate the need for an underhood clutch pump.

Jeff King, marketing manager, says the new system provides greater flow and pressure, easier installation, less noise with no hydraulics in the cab, and easier service and maintenance. The ergonomic electronic controls are easier to reach in the cab.

Access www.parker.com/chelsea for complete details.

All-electric reefer unit for Isuzu trucks

Isuzu Commercial Truck of America Inc. has an all-electric refrigeration unit that eliminates the need for a diesel motor to run the compressor on refrigerated trucks.

The AuraGen generator driven by the truck's engine provides the power required to operate the refrigeration unit. An optional battery back-up system allows the refrigeration system to keep running when the truck's engine is not operating. As soon as the vehicle engine is turned on, the AuraGen automatically recharges the battery pack.

According to Global Refrigeration Systems, manufacturer of the unit, fleets can save approximately $4,000 per truck annually in fuel and maintenance costs based on 2,000 hours of operation. The system is environmentally friendly because no emissions are released to the atmosphere. Using the optional battery pack, this system provides additional cost savings and reduced emissions by not requiring the truck engine to idle while unloading deliveries.

The refrigeration unit weighs 465 pounds and produces an airflow of 1,700 cubic feet/minute. The AuraGen produces 5 to 8.5 kilowatts of power and weighs 112 pounds. In-cab controls permit temperature selection and monitoring of the system. For more information, visit isuzucv.com.

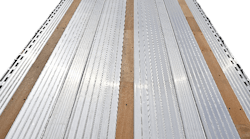

Powerbrace adds 10-inch aluminum hinges

Powerbrace Corporation has created two new 10-inch cast aluminum hinge assemblies in response to demands from specialty trailer manufacturers (horse, livestock, utility, and cargo). The new hinges are also ideal for truck bodies, toolboxes, and other metal cabinets. Offered in both 180- and 270-degree rotation, these 10-inch hinges provide another product option to the already existing 8-inch hinge version, also available in both 180° and 270° rotation.

All four aluminum hinge assemblies have a polished finish and offer an alternative to conventional strap hinges made of steel, which typically rust and corrode.

For more information, visit www.powerbrace.com.

United Truck Bodies going national

United Truck Bodies has been in Phoenix AZ for 15 years as an outgrowth of Drake Equipment of Sioux Falls SD, and branched out into utility bodies with the 2005 purchase of Utility Truck Body of Oakland CA. The tooling and equipment were moved to Phoenix and Utility Truck Body was renamed United Truck Body. Now the company is expanding its sales territory for heavy-duty utility bodies, such as this example exhibited at the NTEA Work Truck Show in Atlanta.

Among the features of this 11-ft body are crane reinforcement for up to a 10,000-lb capacity crane, raised front compartments on the street side for oxygen and acetylene tanks, a heavy-duty workbench style bumper with a large through-box for storage of long tools, and a patented interlaced understructure.

System simplifies ISO container repair

Until now, centers that repair damaged ISO containers had to fabricate replacement lockrods from components they procured from various sources. The problem was always getting consistent quality components when needed and at an affordable price.

Powerbrace Corporation has solved this problem by introducing a new repair system designed specifically for intermodal containers. The program consists of two standard-length universal one-inch factory-galvanized lockrods that repair virtually any container.

These lockrods offer a precise fit every time and are available in lengths for 8'-6" and 9'-6" containers. The heavy-duty OEM replacement lockrods come factory-assembled, complete with one cam and four precisely positioned factory-welded anti-rack rings that virtually eliminate the struggle with component assembly in the field. The repair technician simply welds the remaining unattached cam and the handle assembly at their appropriate replacement positions and mounts the lockrod with a Powerbrace mounting hardware kit.

Because Powerbrace replacement container lockrods are specifically manufactured for container repair, their properly matched cams and keepers ensure smooth door closure and a tight seal to protect the cargo. Powerbrace's 55,000-psi heavy-duty alloy tubing maintains the integrity of the door/end-frame system.

For more information, visit www.powerbrace.com.

Scoop Dogg joins

Snow Dogg line

Among the many new products introduced by Buyers Products at the recent NTEA Work Truck Show in Atlanta were the Scoop Dogg snow pusher for use with front end loaders, backhoes, and skid-steer loaders (pictured in the foreground), and a new tarping system for dump trucks (background).

Visit www.buyersproducts.com for more information.

Johnson Matthey diesel emissions system

proves older can be cleaner than newer

Johnson Matthey's latest diesel emissions technology, the SCRT system, has demonstrated in a trial, using a fleet of 16 older trucks owned by a Northern California grocery store chain, that it is possible that older can be cleaner.

Results were released recently of a demonstration using a number of older Class 8 grocery trucks retrofitted with Johnson Matthey's new SCRT four-way control system. Working with partner Cummins Emissions Solutions, Johnson Matthey tested its emissions system for more than 1,000 hours as the trucks traveled throughout Northern California hauling grocery products to Raley's family of grocery stores.

The demonstration program involved a local partnership among Raley's, the Sacramento Metropolitan Air Quality Management District (SMAQMD), and the Sacramento Emergency Clean Air and Transportation program (SECAT).

The four-way SCRT exhaust emission control system combines Johnson Matthey's patented two-stage CRT particulate filter system (to reduce particulate matter by more than 85%) with a selective catalytic reduction (SCR) catalyst that reduces nitrogen oxides (NOx) between 60% to 80%. It also reduces carbon monoxide and hydrocarbons by more than 90 percent. The result is a four-year-old truck with NOx emissions lower than those of a brand-new 2008 truck.

The findings of the 1,000-hour test were that the SCRT system reduced NOx in Raley's trucks by an average of 84 percent compared with pre-retrofit levels. The trucks involved had 2004 Cummins, 400-horsepower ISM engines with an EGR (exhaust gas recirculation) system. The ISM is a commonly used engine in Class 8 trucks hauling heavy loads.

The next stage for this technology is verification by the California Air Resources Board and the United States Environmental Protection Agency.

Johnson Matthey has nearly 50 demonstration units running in California and Texas. After thousands of hours of operation, the SCRT system retrofits on both EGR and non-EGR engines have reduced NOx emissions by as much as 84%.

Redneck an official NATDA parts distributor

Redneck Trailer Supplies has been announced as the official trailer parts distributor for the North American Trailer Dealers Association (NATDA). Redneck has made a three-year commitment to the organization as an official sponsor of NATDA.

NATDA bands together light- and medium-duty trailer dealers that handle livestock, horse, utility, cargo, and other trailers. The association has developed programs to help trailer dealers, such as trailer-specific insurance, health insurance, trailer rental programs, and discounted shipping and freight services.

A trailer parts distribution company, Springfield MO-based Redneck has been in business since 1979. It serves the United States and parts of Canada from its 19 branch locations. The company has developed several programs specifically for trailer dealers and their customers, including packaged trailer repair parts. Redneck also offers customer training, product knowledge, and promotes sharing of information within the trailer and towing industries.

DuraSeal adapted for long-haul truck use

Goodyear Tire & Rubber Company has adapted its self-sealing commercial tire technology on a broader scale for use on long-haul trucks.

The new Unisteel G316 LHT line-haul trailer tire featuring DuraSeal technology allows semi-trucks to continue operating after a tire is punctured by road debris up to ¼-inch diameter in the repairable tread area, reducing vehicle downtime and service calls.

Already proven in mixed-service applications, the technology uses a gel-like, solvent-free compound built into the inner liner of the tire. It consistently and instantly seals punctures with gel flowing into void areas and around objects less than ¼-inch in diameter.

Goodyear is using DuraSeal in the G316 LHT trailer tire, which also is available in a fuel-efficient version featuring Fuel Max Technology.

TODCO PolarTek door is graphics-friendly

TODCO's new PolarTek overhead refrigerated door is doing double duty, thanks to its high thermal efficiency rating as well as its smooth surface, making it ideal for use with or without graphics.

PolarTek is constructed of extruded hollow-core polycomposite panels, offering a smooth, quality finish that makes graphic applications very appealing — and painting optional. The panels are foamed in place with moisture-resistant, thermal-efficient polyurethane foam, whose thousands of tiny air pockets prevent Btu loss while adding strength and rigidity to the door.

“More and more of today's refrigerated trailers are used as mobile billboards,” said Scott Blackford, TODCO vice-president of sales and marketing. “Our PolarTek doors can enhance a fleet's marketing efforts and aesthetics because they're very decal-, paint-, and graphics-friendly.”

E-mail Blackford at [email protected] for more information.

Wire thread inserts do away with tangs

Independent tests prove that bolts installed into Spiralock's new Drive Notch (DN) Wire Thread Inserts have shown no loss of tension after 24 hours of continuous vibration testing (one million cycles) and no indication of fatigue problems.

Using the DN installation tool, the inserts simply thread into any NAS 1130, STI tapped hole with no need to break off, retrieve, or account for tangs — because there are no tangs.

Uing a DN insert is straightforward: drill an appropriate-size hole, tap the hole with an STI tap, and install the insert. During installation, the DN installation tool locks into the insert DN to thread the insert into the tapped hole.

DN inserts use Spiralock's patented 30-degree “wedge” ramp formed into a five-sided wire. When wound into a coil shape, it creates the ramp at the root of the female thread. Under clamp load, the crests of the threads on any standard male bolt are drawn tightly against the wedge ramp. This eliminates sideways motion and distributes the threaded joint's load throughout all engaged threads.

These inserts offer improved joint integrity in softer materials such as aluminum, zinc, magnesium, and plastic. They eliminate stress in the parent material as there is no staking, keys or lock rings necessary to hold them in place. In addition, they resist galling as well as chemical and environmental corrosion. Visit www.spiralock.com for more information.

Waytek offers productsfrom Klein Tools

Waytek Inc, a distributor of electrical wiring supplies, now carries four new products from Klein Tools, including the Klein Kurve Wire Stripper, the Journeyman Crimper/Cutter, the Continuity Tester, and the Compound-Action Specialty Crimper.

The new Klein-Kurve tool is a precision wire stripper/cutter that strips and cuts 18- through 10-gauge solid wire and 20- through 12-gauge stranded wire. Shear-type blades allow for clean cuts.

Waytek's Journeyman Crimper/Cutter is designed for working in confined spaces and crimps insulated and non-insulated 22- through 10-gauge solderless terminals and connectors.

The Compound-Action Specialty Crimper tool crimps 22- through 10-gauge insulated terminals to meet or exceed MIL-SPEC pull-out tests.

The Continuity Tester quickly reveals shorts or broken circuits in all types of electrical devices and controls. The bulb in the handle glows when a circuit is complete.

For more information, e-mail [email protected].

Azure signs an MOU for LEEP systems

Azure Dynamics Corporation, a developer of hybrid electric and electric powertrains for commercial vehicles, has signed a memorandum of understanding (MOU) with a manufacturer of aerial boom trucks for the electric utility, telecommunications, and contractor markets. The MOU includes the branding, marketing, and sale of Azure's Low Emission Electric Power (LEEP) systems within the electric utility and telecom markets.

Under the proposed terms of the MOU, Azure will supply LEEP systems specifically adapted to boom truck applications. The systems will be integrated into its trucks, and the manufacturer has agreed to brand and market the product throughout its North American truck body market segment.

LEEP delivers significant reductions in fuel utilization and emission levels. Its hybrid technology stores energy when a vehicle's engine is running. When the engine is off, the stored energy is used to power the hydraulic boom and other auxiliary power requirements.