When Hyundai Translead began to plan its new 154,000-square-foot building for high-speed production of dry-freight van trailers, the manufacturer had a ready source for ideas — its parent company.

When it comes to automation, no one automates like auto manufacturers. And that includes Hyundai Motors, the world's sixth-largest automobile manufacturer and a source for much of the tooling that helps speed production and maintains quality.

“It's great to have these resources,” says Garry Shidler, vice-president of manufacturing. “In putting this plant together, we were able to draw from Hyundai and its suppliers in Korea.”

That is particularly the case with tooling.

“We have backups and backups of backups,” Shidler says. “If a machine fails, we don't need bandages.”

The new building is part of the sprawling Hyundai Translead complex in Tijuana, Mexico, just south of the U S border. It was built virtually from scratch at a place where the company used to remanufacture container chassis. Surrounding the new building are series of other plants where Hyundai Translead produces a diverse product line, including refrigerated trailers, domestic containers, drop-frames, container chassis, and converter dollies.

The Tijuana complex — with just over 200 acres — has five lines for producing some form of van. That includes domestic containers, drop-frame vans, and refrigerated trailers. The company also operates two lines for producing container chassis and another to assemble converter dollies. While that's the general idea, Hyundai Translead can quickly change them out for other products.

“It's hard to believe,” Shidler says while looking at an assembly line filled with container chassis in another building elsewhere on the campus. “We were building domestic containers here two days ago.”

That's not the case at the H line, where dry vans and domestic containers are the only products on the menu.

Thinking about it

The H line is the result of an extensive series of meetings involving input from multiple sources led by Harry Cho, Hyundai Translead's plant manager.

“We asked ourselves a lot of questions,” Shidler says. “For example, what would be the best way to move trailers through the assembly line? How do we feed the assembly line? What if the specs are different?”

The result is a $15.5-million expansion. The project includes some innovative tooling that will help increase production capacity for vans and domestic containers by 30%-in part through the use of jigs and fixtures that Hyundai Translead was able to obtain only through its affiliation with Hyundai's automobile manufacturing operation.

Open for business

The fruit of all that planning began to appear in April. Designed to produce 50 trailers per day, the H line has been ramping up steadily. Employment on the line is now up to 150, and the plant is operating two shifts.

The inevitable kinks involved in an operation of this size are being worked out — not surprising for a trailer manufacturer that has been ISO-9001 certified as far back as 1996.

One of the obstacles the company has had to overcome has been language. After all, Hyundai Translead is headquartered in San Diego. Its manufacturing plant is in Mexico, and the parent company is Korea.

But knowing how to speak English, Spanish, and Korean is not enough. Some of the employees at the Tijuana plant come from southern Mexico where indigenous Indian dialects are spoken.

To help improve communications in a plant where multiple languages are spoken, Hyundai relies heavily on graphics, icons, and pictures during training sessions and in day-to-day operations. The company's diversity is now one of its greatest strengths, as it leverages knowledge and wisdom from all cultures forming one unified Hyundai Translead culture.

Training the influx of new employees may have been a significant undertaking, but it also has some advantages.

“The H line has no used equipment — everything is new,” Shidler says. “And we have staffed the line with a lot of employees who are new to Hyundai Translead. There's a reason for that. This line produces trailers in a different way, and we wanted to avoid the ‘We've never done it that way before’ syndrome.

“We are always trying to innovate. Our entire plant is a relatively new operation — particularly the H line. We don't receive the resistance that we otherwise might from long-term employees who don't like change. We are always trying to develop better ways to produce trailers.”

Firing the robots

When thinking about how automobile manufacturers automate production, robots may be one of the first things that come to mind.

Hyundai Translead has employed robots in the past. But management fired its robots and opted for other forms of automation instead when equipping the H line.

“A lot of the technology we use on the H line is the same as what we have been using,” Shidler says. “But we aren't using any robots. We bought two of them in 2001, but the technology then was changing so fast that they were out of date before they paid for themselves. With the H line, we have more automation than ever before, but we are doing it without robots. Instead, the tooling we have has been available for years. We have taken ideas from our Korean operations and put them into play. It has worked for them, and now it is working for us. Some of the equipment we have in this plant is available to us only because we are part of Hyundai.”

Of course, not everything that the company uses to produce cars is feasible for use in trailer manufacturing.

“Hyundai produces 300,000 cars a year at its plant in Alabama,” Shidler says. “But we don't have 300,000 trailers per year to spread out the cost of some of the equipment they use.”

Eliminating bottlenecks

In addition to deciding against using robots in the H line, the company also chose not to rely on a conveyor system to move trailers through the line. Instead, a cart system moves the trailers from one station to the next.

“The cart system eliminates bottlenecks,” Shidler says. “If something goes wrong, we can throw manpower at it. It's a lot more flexible. And if a conveyor breaks, you're stuck.”

And finally, the company has said no to forklifts.

“We don't allow forklifts,” Shidler says.

So far, it sounds like the Hyundai Translead's H line is more distinct for what it does not have than for what it does. But a basic approach to assembling trailers has made forklifts and other common equipment of very limited value.

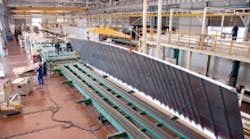

Material flow is straight, and subassemblies are produced close to where they are needed on the line. For example, the side table is located at the beginning of the assembly line. It feeds directly into the assembly line.

Front walls are built in the same area. Completed walls are loaded onto a cart that is capable of delivering six completed front walls to the line.

Floors also feed directly into the line.

“We preassemble every component we produce,” Shidler says. “The assembly line is not the place for fabrication.”

Gang drills, punching, and rivet machines reduce much of the time required to fasten flooring, side sheets, and extrusions.

“A lot of what we have on the H line is equipment that you see on other lines,” Shidler says. “But the efficiency that we have here is better than that found on our other lines.”

Maximizing efficiency

Much of what Hyundai Translead has learned in the brief time that the H line has been in operation is being applied on other lines in the plant.

“We already have transformed our A line (which produces high-volume specialized trailers), and our B line (refrigerated trailers plus some dry-freight vans and containers). One of the big things has been trying to figure out how to eliminate forklifts in other lines at the plant. We've been working on other things, too, like keeping the floors spotless, becoming more and more disciplined. We are trying to make our trailer plants more and more like automotive facilities.”

Much of it is mental. Part of it is procedural. And some of it is achieved through the acquisition of plant equipment designed to reduce labor — both in terms of how much time employees need to complete a job and how much physical exertion they expend in doing so.

Among the fixtures and equipment found in the H line that help Hyundai achieve those objectives:

-

Greater use of scissors lifts.

-

Automated roof assembly machine.

-

Improved mounting stations.

-

Balancing devices that can move heavy loads with fewer people.

“A good example — our landing leg assembly installation,” Shidler says. “That used to take three people. We have it down to one. The other two people that used to work in that area are now doing other jobs in the plant.”

Maximizing labor

Helping employees achieve maximum productivity is important in any country, and the higher the wage rate, the greater the effect that efficiency has on the bottom line.

“People think that the labor rate in Mexico is a lot less than in the United States,” Shidler says. “But dollar for dollar (or peso for peso), our overall labor cost here is comparable to that found in the United States. That's because of the fringes we pay. According to Mexican law, employers are responsible for the welfare of their employees from the time the employee leaves his house until he comes home. It's not uncommon at maquiladora plants to provide point-to-point pick-up and drop-off services. We have a bus service to do that. We also have a fulltime doctor on staff. We offer full laundry service, a barber shop, and a cafeteria, and we provide uniforms.”

Of course, Hyundai Translead is not alone in providing employees with these amenities. Other plants in the area do the same thing, including a series of consumer electronics manufacturers such as Samsung, Sanyo, and Toshiba.

Minimizing freight

The Hyundai Translead plant is just south of the southwest corner of the United States. Short of putting a plant in Alaska or Hawaii, the company could not get farther away from the freight centers of the Northeast and Midwest.

But geography is not the disadvantage that it might seem, thanks to agreements Hyundai Translead has with its neighboring manufacturers in Tijuana. These plants generate a lot of freight, which helps reduce the cost of getting Hyundai Translead trailers to major markets.

“Detroit, Dallas, New York. They all benefit from our ability to ship trailers this way,” says Stuart James, vice-president of sales. “We can serve dealers throughout the U S and be competitive from a freight standpoint.”

An efficient plant also helps. And with the addition of the H line, the Hyundai plant in Tijuana just became more efficient.

“You know, I grew up in Indiana in an agricultural state,” Shidler says. “The H line is a little like being back home in Indiana. We put in a lot of work to make this happen, and now our efforts are really beginning to produce.”